Steel Bender

At Radford University, I built this steel bender because of a recurring need for steel curves in our scenery. After reviewing two similar machines, I researched, designed, and built this one. The basic concept of this machine is simple. By pressing the steel to beyond its yield point and then rolling it through a series of rollers designed to withstand this force, one can create a slight curve in a steel beam. If this is repeated for several passes, a curve to virtually any radius can be created.

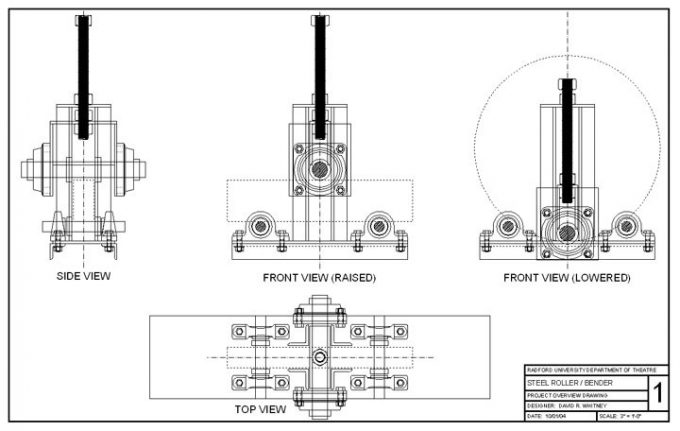

A 3D isometric drawing of the steel curve-bender.

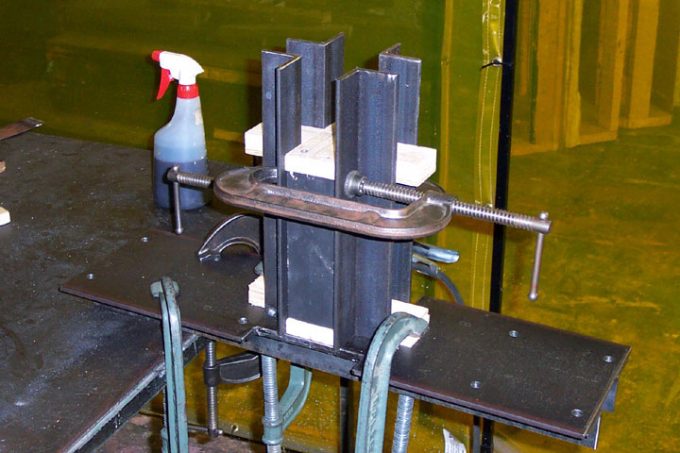

The vertical supports held in place with a wooden jig and clamped down, ready to be welded.

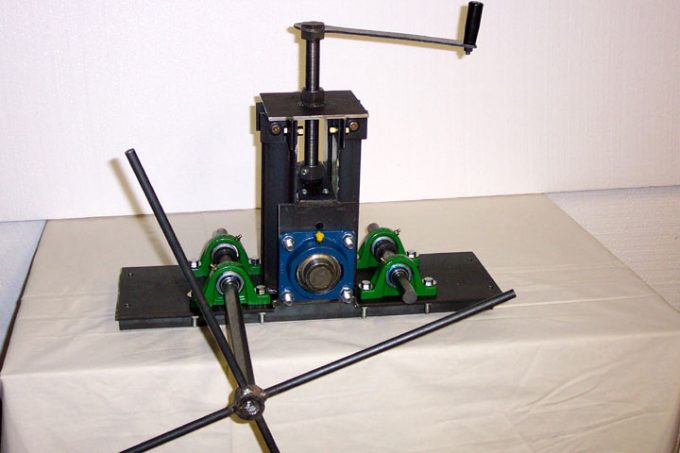

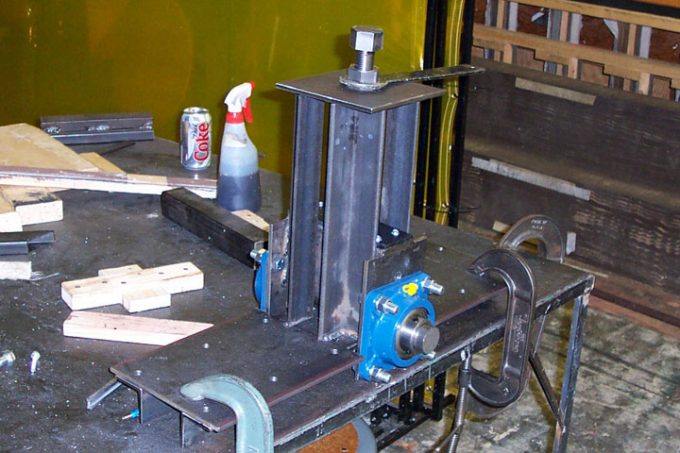

The completed carriage unit.

The carriage unit about to be welded to the vertical supports and base.

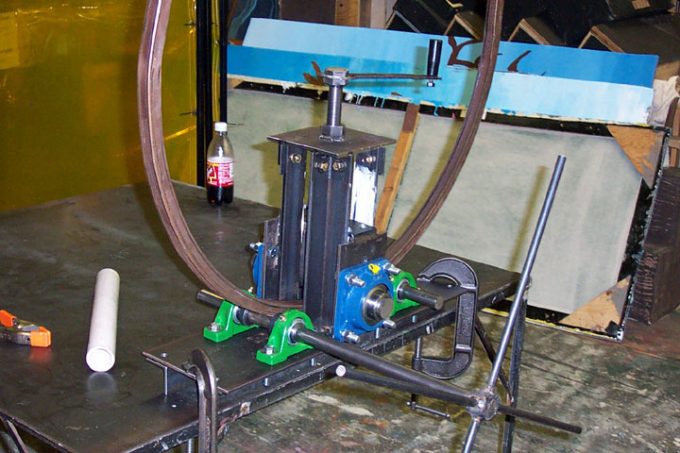

The completed steel curve-bender in action, about to bend a beam of 1″ x 1″ square tube steel.

After about 25 passes through the bender and about 45 minutes of work, the steel beam has a diameter of about 3 feet.